Your automated welding process is unique. Your materials, workpiece geometry, equipment, process schedule, and manufacturing environment make your process one-of-a-kind. So why allow an in-process monitoring application provider to sell you a one-size-fits-all approach? This article introduces InnerVoice's modular plugin environment and explains why InnerVoice is the most powerful in-process monitoring solution on the market.

InnerVoice was designed from the ground up as a modular software platform where plugins allow InnerVoice's powerful data analytics and quality classification techniques to be applied to almost any automated welding process. Plugins also provide capabilities that are unique to the customer's needs, for example, a data reader for a proprietary file format, a signal retriever with a customer-specific filtering technique, or a disseminator that communicates quality feedback directly to a PLC or QMS database. Plugins provide the flexibility to meet a customer's unique manufacturing needs and quality assurance requirements.

The plugin software architecture pattern is not new. In fact, plugin capabilities have been around since the mid-1970s [1]. In general, the pattern consists of two components, a core system and plugin modules [2]. The core system provides a framework and a basic set of capabilities for the application's business logic, while plugins enhance the core system by extending the application with additional capabilities. Plugins can be developed and tested in isolation from the core system thereby ensuring that the core components remain protected, stable, and maintainable.

For InnerVoice, the core system includes the necessary components to support a full-featured, modern-day desktop application including a sophisticated graphical user interface, a help system, and the means to effortlessly receive application updates from the cloud. Most importantly, the core system includes a data model and the business logic to support an in-process monitoring framework.

Even though InnerVoice is sold as a "shrink-wrapped" software package, it is commonly referred to as a “platform” because it is composed of the core system along with a variety of plugins. The core system is packaged with every distribution of InnerVoice, while the plugins are included according to the customer’s manufacturing environment and quality assurance needs. Plugins are the method InnerVoice uses to achieve an infinitely configurable system.

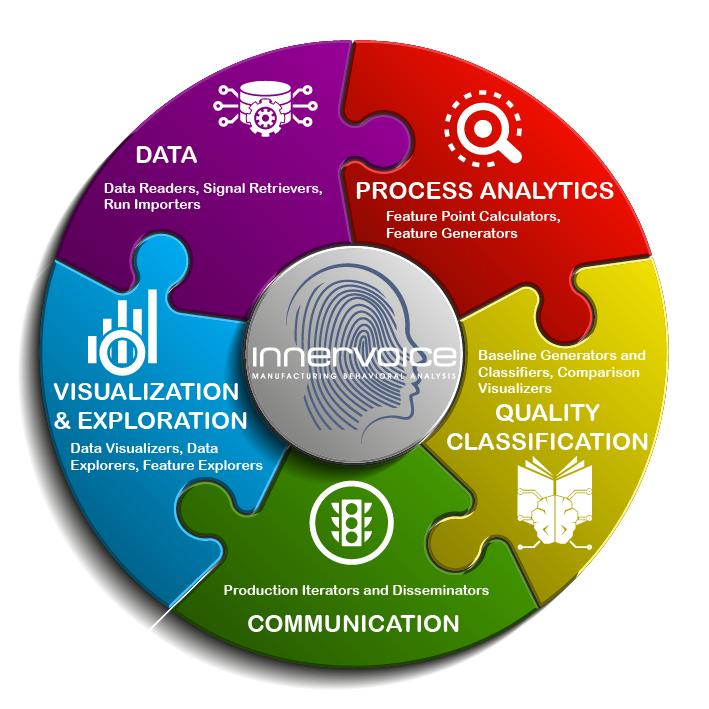

The following figure illustrates the five broad categories of plugins available in InnerVoice.

Each category of plugins contains one or more services that enables InnerVoice to be uniquely configured according to the customer's needs. InnerVoice relies upon services to address each step in the in-process monitoring lifecycle. Services can be custom developed to address a unique need of the customer. For example, InnerVoice has dozens of Data Reader services that provide the ability to read a wide variety of different file formats.

While the number of services available in InnerVoice is too involved to discuss in a single article, the end result is a platform of capabilities that can be uniquely tailored to the customer's manufacturing quality assurance needs. InnerVoice leverages plugins to provide a best-in-class in-process monitoring solution.

The advantages of a plugin software architecture are numerous. Plugins reduce the software complexity and development costs by supporting a modular, component-based framework. A modular framework promotes code stability, security, and transparency. Most importantly, from an end-user perspective, a plugin software architecture provides InnerVoice with:

- Configurability: InnerVoice's services provide the flexibility to solve even the most challenging automated welding environment.

- Simplicity: InnerVoice's user interface is clean and simple. The end user sees only those services and capabilities that are relevant to their manufacturing process and quality assurance needs. There is no clutter from unnecessary or extraneous services.

- Extensibility: InnerVoice's functionality can be increased or enhanced through the addition of plugins to suit the manufacturer's evolving or changing needs.

Your manufacturing environment and quality assurance needs are unique. Do not let your in-process monitoring application provider force you into a round hole. Each installation of InnerVoice is a unique reflection of a manufacturer's process characteristics and quality assurance requirements. Modular by design and configurable by the end user, InnerVoice integrates seamlessly with your manufacturing process to support your quality assurance best practices.

Contact us to learn more about how InnerVoice can be customized to solve your automated welding process quality assurance needs.

--

[1] "Plug-in (computing)" Wikipedia, Wikimedia Foundation, 15 February 2023, en.wikipedia.org/wiki/Plug-in_(computing).

[2] M. Richards, "Software Architecture Patterns", O'Reilly Media, Inc.