Capabilities

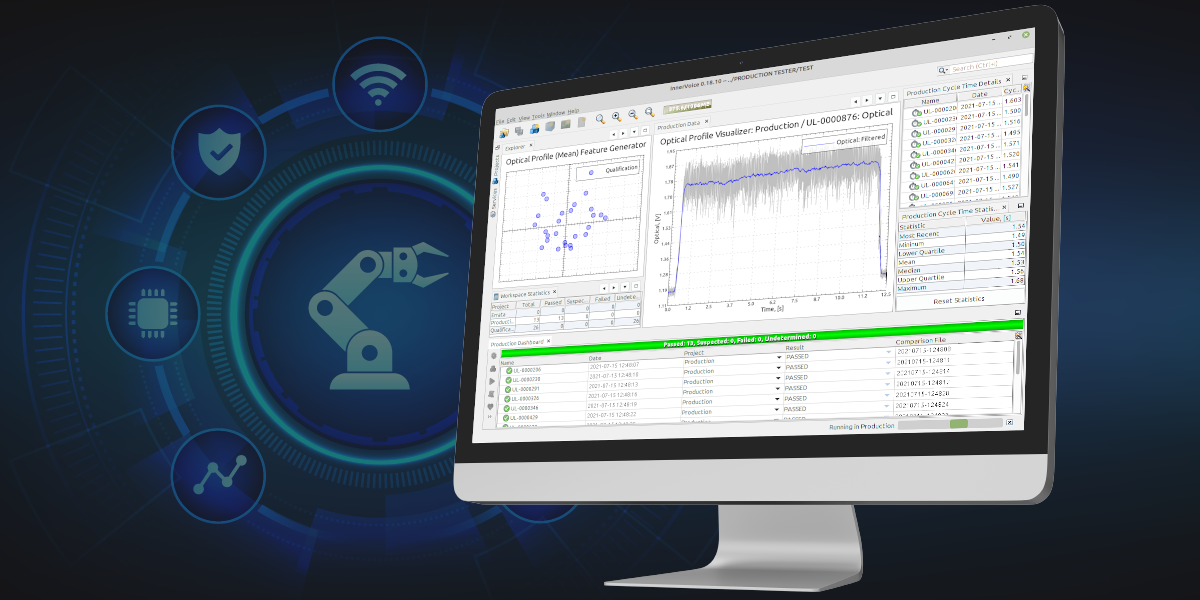

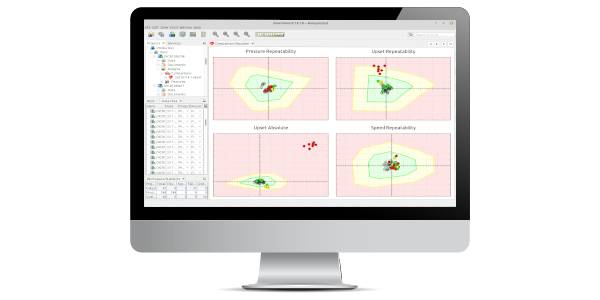

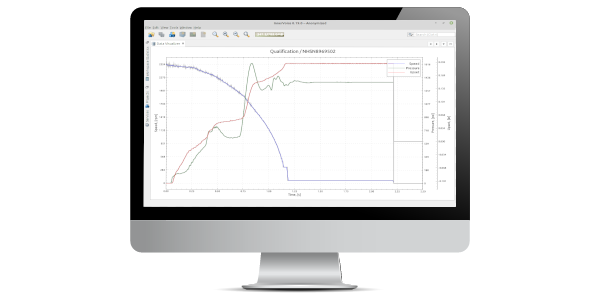

InnerVoice detects defects in real-time by alerting the manufacturer of abnormal process behavior. It was designed from the ground up to be a pluggable architecture and provides four main capabilities:

Visualize

Explore

Analyze

Communicate

InnerVoice communicates directly with PLCs controlling the manufacturing process or

with the manufacturer's IT database. This direct line of communication

provides data-driven, actionable intelligence and enables real-time

visibility and fine-grained control over the manufacturing process. Flaws are identified, contained, and corrected without further value-added downstream processing.

Processes

Rotary Friction Welding

Features

Responsive

Provides real-time visibility into the manufacturing process without adversely affecting your production cycle time.

Insightful

Actionable

Vigilant

Connectable

Intelligent

Flexible

Singular

Preventative

Certainty

Sustainable

Transparent

Frequently Asked Questions

-

What is InnerVoice?

InnerVoice is a real-time, in-process monitoring hardware and software platform for manufacturing quality assurance.

For more information, see our article Introducing InnerVoice. - What is in-process monitoring?

- What are the benefits of in-process monitoring?

- What is In-Process Quality Assurance (IPQA)?

- We already collect data, so why do we need InnerVoice?

- Can InnerVoice replace destructive and non-destructive post-process inspection?

- What manufacturing processes can InnerVoice monitor?

- Do you offer data collection and analysis services?

- Is InnerVoice a cloud-based service?

- Can you retrofit older machines?

Resources

Outsourcing Weld Process Development Without Objective, Third-Party Surveillance

Outsourcing weld process development to an experienced contract welding service provider is common for many industries, including the manufacturers of flight critical components, turbomachinery, and precision medical parts as well as for small-scale research and development applications. Contract...

Read More...Increase Productivity by Detecting Off-Normal Conditions Immediately

Reducing the manufacturing cycle time serves a vital role in increasing the revenue of an organization. Managers are therefore reluctant to consider implementing additional layers of quality assurance that might negatively impact their productivity or manufacturing cycle time. This article...

Read More...Defect Detection: In-Process Monitoring vs. Non-Destructive Testing

The claim that InnerVoice, or any in-process monitoring capability, can detect defects is a misnomer. In actuality, in-process monitoring infers a defect-free part by directly interogating the process physics and dynamics.

Read More...Contact Information

Fairhope, Alabama, USA

+1 (505) 231-7525